Advantages of spiral duct in ventilation industry

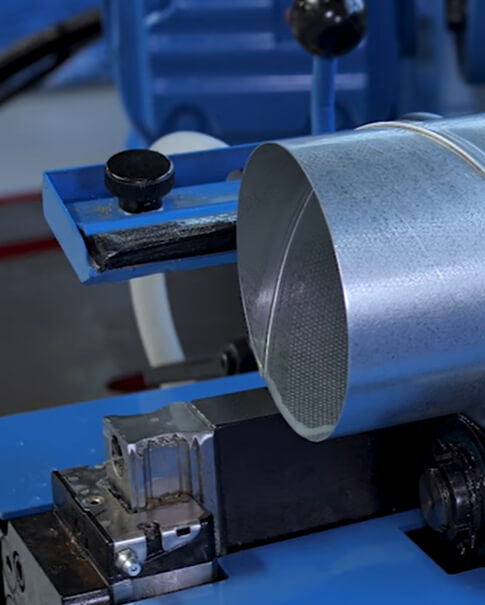

Spiral duct, since entering the market due to its excellent performance and low cost, ventilation in the application of air conditioning system continues to improve, most of the products are widely used in shipbuilding, ventilation, purification, dust removal, airports, tunnel bridge construction and other industries, such as spiral fan after years of research and development of Swiss advanced technology spiral duct machine has reached the domestic advanced level, volume pipe diameter 80 -1600 mm, processing thickness 0.4-1.2mm, Spiral duct machine company has a number of pipeline production lines. The main uses of spiral ducts are as follows:

(1) Ventilation system: send fresh air and exhaust, discharge harmful gases outdoors, and send outdoor fresh air indoors. In general, the flow of the ventilation system is very large, so it is required to use less resistance of the air transmission pipe, in order to save cost and operating costs - spiral duct is the most suitable. Under normal circumstances, galvanized iron pipes are used, and stainless steel pipes are used in corrosive and particularly humid places.

(2) Air conditioning system: The spiral air duct can be internally coated with insulation material, with a beautiful appearance.

(3) Exhaust smoke system: hotels, restaurants, hotel kitchens have a lot of smoke, need to discharge, the use of spiral air duct is appropriate, good strength, economic and practical.

(4) Dust removal system: The collection and transportation of dust removal device can use spiral air ducts.

(5) Bulk material transportation: There are various pneumatic conveying systems, where some finer and looser material particles can be transported using spiral air ducts, with low cost and good results.