Why More HVAC Manufacturers Choose the Auto Duct Production Line

Oct 09, 2025

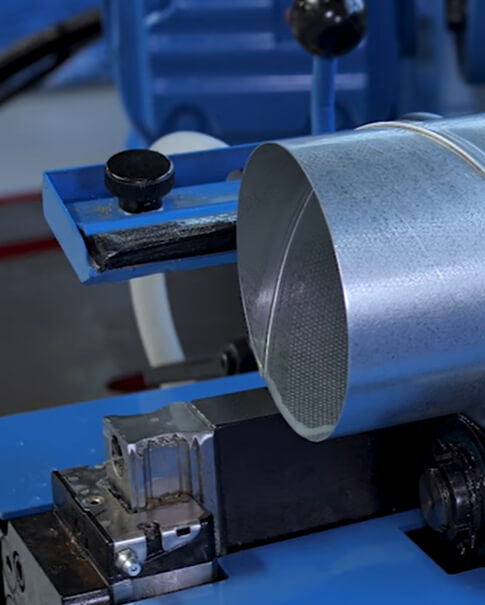

In modern HVAC manufacturing, speed, accuracy, and automation define competitiveness. The Auto Duct Production Line is a fully automatic solution that integrates feeding, leveling, beading, notching, shearing, and folding — all in one system. This innovation allows manufacturers to produce rectangular air ducts with exceptional precision and efficiency.

What Is an Auto Duct Production Line?

An Auto Duct Production Line is an advanced sheet metal fabrication system used in air duct manufacturing. It automates the entire duct-making process — from uncoiling to folding — significantly reducing manual labor and material waste.

By combining multiple production steps into a single automated workflow, the Auto Duct Production Line helps companies improve quality consistency while meeting international HVAC standards such as SMACNA, DW144, and ASHRAE.

Who Needs the Auto Duct Production Line?

The Auto Duct Production Line is essential for businesses that require high efficiency, precision, and scalability in their duct fabrication process:

🏗️ HVAC System Manufacturers

These companies supply ventilation ducts for large commercial buildings, airports, factories, and hospitals. Automation ensures their projects stay on schedule and meet strict specifications.

🏭 Sheet Metal Fabrication Workshops

Workshops looking to expand production capacity and reduce labor dependency can rely on automatic duct lines to achieve faster turnaround times with fewer operators.

🧰 Engineering and Construction Contractors

Contractors responsible for on-site HVAC installation benefit from in-house duct fabrication, improving project control and cost efficiency.

🌍 Exporters & OEM Duct Suppliers

Businesses serving overseas HVAC markets can use automated production to guarantee uniform quality and meet client standards across multiple regions.

How the Auto Duct Production Line Improves Efficiency

The Auto Duct Production Line automates each step of the duct-making process to ensure a seamless, error-free workflow:

1️⃣ Automatic Coil Feeding

Multiple coils can be loaded simultaneously, ensuring uninterrupted material supply.

2️⃣ Leveling & Beading

Guarantees perfectly flat sheets and adds rigidity to ducts for long-term durability.

3️⃣ Notching & Punching

Automated corner notching improves assembly accuracy and reduces manual cutting errors.

4️⃣ Shearing & Folding

High-speed shearing and bending deliver uniform duct dimensions and airtight seams.

The result: higher production capacity, fewer defects, and better cost control.

Why It’s a Smart Investment for HVAC Businesses

Upgrading to an Auto Duct Production Line can dramatically change how your factory operates:

💰 Save Labor Costs: One operator can manage the full line.

⚙️ Stable Product Quality: Automation reduces human error.

⏱️ Increase Production Output: Continuous, high-speed operation.

🌱 Energy-Saving System: Servo-driven motors reduce power use.

📈 Faster ROI: Suitable for both domestic manufacturing and export markets.

Whether you’re producing ducts for a commercial air conditioning project, a metro ventilation system, or prefabricated modular buildings, automation ensures efficiency and reliability.

Real-World Applications

Industrial HVAC system manufacturing

Shopping mall and airport duct installation

Hospital and cleanroom air distribution systems

Prefabricated and modular building projects

Wherever precision duct fabrication is required, the Auto Duct Production Line offers unmatched performance and consistency.

3️⃣ 开槽和冲孔