Reel shear beading machine is a combination of shearing and beading. Operator only needs to change shearing mould or beading mould. Reel shear beading machine is used to cut, bead/groove thin sheet metal. The advantages of reel shear beading machine include adjustable cutting width, easy operation and small size. Therefore,it's suitable for processing HVAC duct on site.

HS Code :

8455229090Min. Order :

One SetManufacturing Time :

Almost IN STOCKPayment Terms :

TT,LC,West Union etcPacking Method :

Exporting wooden boxQuality Guarantee Period :

18 month from B 'L issued dateAnnual Production Capacity :

200 sets machinesCUSTOMER DESIGN OR OEM :

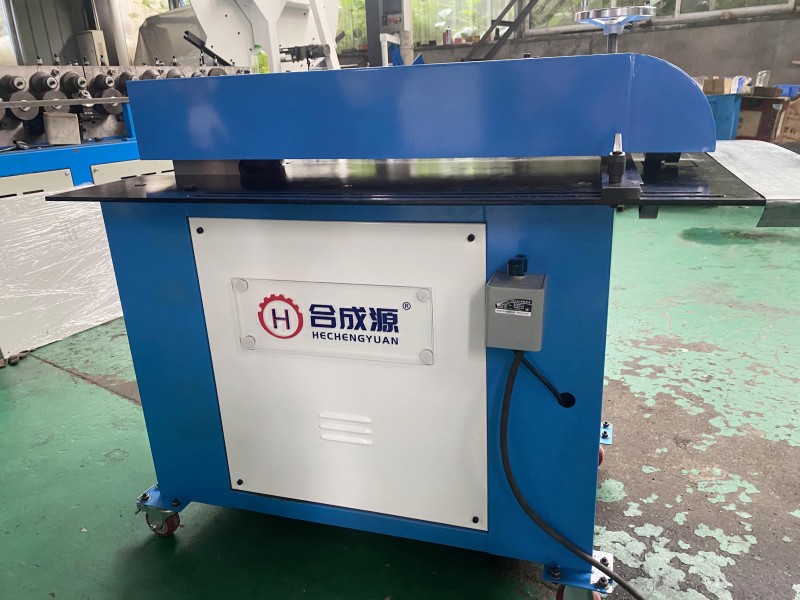

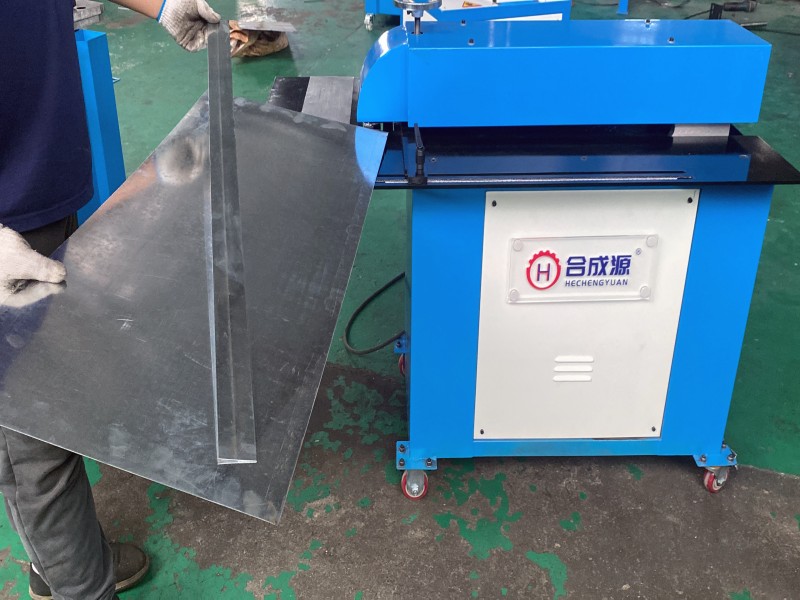

AcceptedHVAC Duct Thin Sheet Metal Reel Shear Beading Machine

I. Reel Shear Beading Machine's Features:

II. Technical Parameters:

1. Machine name: HVAC duct thin sheet metal reel shear beading machine

2. Machine model: HCY-15

3. Sheet thickness: 1.2mm

4. Maximum width: 1250mm

5. Power of motor: 1.5KW

6. Weight: 260KGS

7. Dimension: 1600x630x1120mm

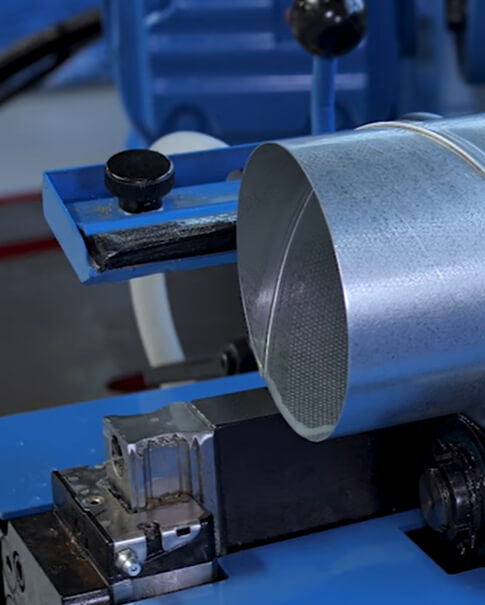

III. Real Photos:

IV. Quality Certifications:

V. RFQ:

1. Are you manufacturer or trading company?

We are manufacturer.

2. What shall we do if don't know how to operate your machine?

We can dispatch our engineers to your country and you can also send your engineers to our factory for learning operation. Besides, there are detailed installation and operating instructions attached, it is very simple. We have telephone and email support at 24 hours per day.

3.How about your machine quality?

HCY company is a mature brand in CHINA,through our 15 years research in technology,our design including structure and detailed security and precision has enhanced greatly,and can match all the CE standard or more strict standard.Our machines distribute worldwide to about 50 countries where there are metal plate industry And where there are our machines,there are good reputation and terminal user satisfaction.

4. What are your payment terms?

We support T/T, L/C, D/P, D/A, Western Union and so on. TT, 30% in advance, 70% balance before the shipment.

5.Can we be your agent?

Yes,we are looking for Global agent we will help agent improve the market ,and supply all the service like machine technical

problem or other after-sales problem, meanwhile ,you can get big discount and commission.

6.Do you accept customer Logo and customized ?

we accept kinds of customized ,including logo and machine .

Hot Tags :