How to operate a spiral air duct machine?

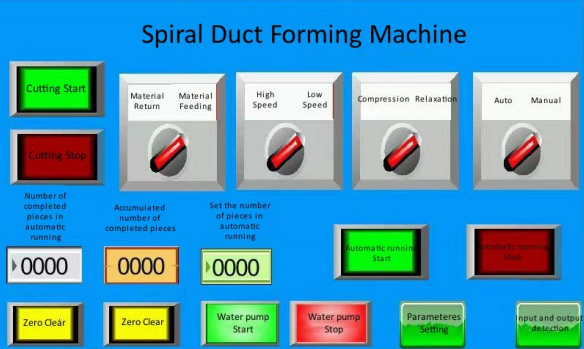

Jan 26, 2024Control interface:

This machine adopts touch screen operation control. The following is an introduction to

the touch screen operation interface and operation buttons.

Before operation, connect the foot switch and fill the water tank with a mixture of water

and emulsified oil;

(1) Material return/feeding: Click 'down' to switch to 'reverse', and the host will forward

and reverse;

(2) Compression/relaxation: Control the compression and relaxation of the upper seam

wheel;

(3) High speed/low speed: can control the high-speed or low-speed operation of the host;

(4) Auto/Manual: Clicking on the [Manual] button allows you to control the host using a

foot switch, while clicking on the [Auto] button does not allow the foot switch to control

the host;

(5) Before starting, click on [Water pump start ];

(6) Speed control knob: used to adjust the engine speed in manual/automatic mode.

Automatic mode:

(1) Set the number of pieces in automatic running: Set the cutting number here;

(2) Automatic running start: Press after setting the cutting quantity;

(3) Automatic running stop: In automatic mode, stop working;

(4) Zero clear: After the cutting quantity is completed, press longer time to clear zero;

(5) Length limit switch: Used to adjust the length of the pipe in automatic mode. Press the

switch to start cutting. Lift the switch to start the machine again, and the cycle works.

Operation method:

(1) Install the steel strip with a width of 137mm on the feeding rack and support it tightly.

Adjust the tailstock according to the scale to the position where the diameter of the

circular pipe matches, and start the water pump.

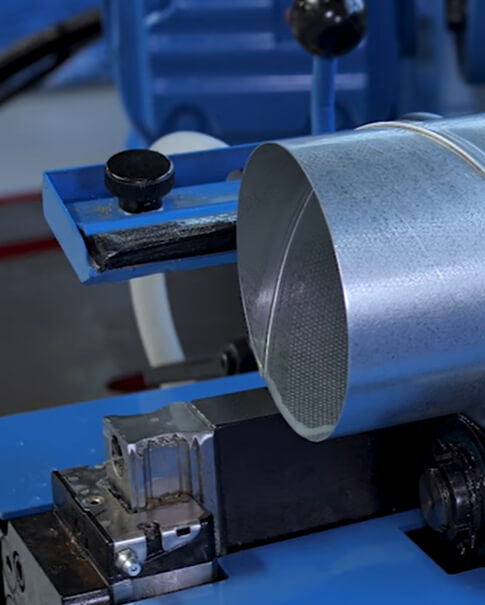

(2) Install the steel strip mold on the mold base according to the diameter of the pipe, and

check whether the lower seaming wheel matches the thickness of the strip.

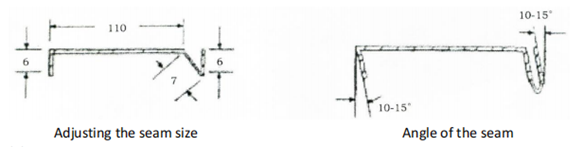

(3) Insert the belt material into the feeding port and use a foot pedal to pass it through

four rolling rollers (six rolling rollers) and the pressure plate, reaching the upper and lower

seam wheels. In this process, adjust the symmetry of the seaming on both sides of the

strip and the angle of the seam.

(4) Use the pedal to slowly turn the strip into a spiral tube shape in the mold, press the

upper pressure wheel tightly, and embed the wheel mouth into the female mouth. Turn

out a small section at a slow speed, then saw the mouth flat, check the diameter of the

round pipe, and fine-tune it if there is any error.

(5) Turn the nozzle to the discharge rack at low speed. Adjust the height of the discharging

rack and the axial parallelism of the rotating tube, and adjust the length and size stroke

switch of the round tube.

(6) With the above adjustment method, after the first tube production, it is necessary to

continue to observe and adjust until the tube can be transferred smoothly.

Come and choose a suitable spiral air duct machine, looking forward to working with you!