Air duct processing product prospects

Sep 12, 2024

As an indispensable and important component in building ventilation systems, air conditioning systems and industrial exhaust systems, air duct processing products are widely used and have broad prospects. The following will elaborate on the application of air duct processing products and their future development prospects from many aspects.

1. Application of air duct processing products

(1) Building ventilation and air conditioning system

In the construction sector, duct processing products are mainly used to construct ventilation and air conditioning systems. Through a properly designed and processed air duct system, indoor air quality can be effectively adjusted to ensure the comfort of living and working. Specifically, the air duct system can bring fresh outdoor air into the room and discharge the dirty indoor air to achieve effective air circulation. In the air conditioning system, the air ducts can also be attached with insulation materials to ensure the effective delivery of cold air or heating while improving the energy efficiency of the system.

(2) Industrial exhaust system

Industrial production processes often produce large amounts of waste gas, smoke and other pollutants, posing a threat to the production environment and employee health. Air duct processing products design and produce exhaust systems to effectively discharge these pollutants and protect the production environment and employee health. Especially in heavy industries such as chemical industry, metallurgy, and electric power, the application of air duct processing products is more extensive and important.

(3) Application in special environment

In places with extremely high environmental requirements such as hospital operating rooms and clean workshops, air duct processing products need to use special materials and processes to ensure the cleanliness and sterility of air circulation. These special air ducts not only require materials that are corrosion-resistant and easy to clean, but also require high sealing and air tightness to ensure indoor air cleanliness.

(4)Furniture manufacturing industry

During the furniture manufacturing process, especially wood processing and painting operations, a large amount of moisture and harmful gases are generated. Air duct processing products can provide customized ventilation management solutions for furniture factories to eliminate harmful gases and improve air quality, thus ensuring the health of employees and the quality of the production environment. Through properly designed and constructed air duct systems, furniture factories can significantly improve the production environment and enhance product quality.

2. Prospects of air duct processing products

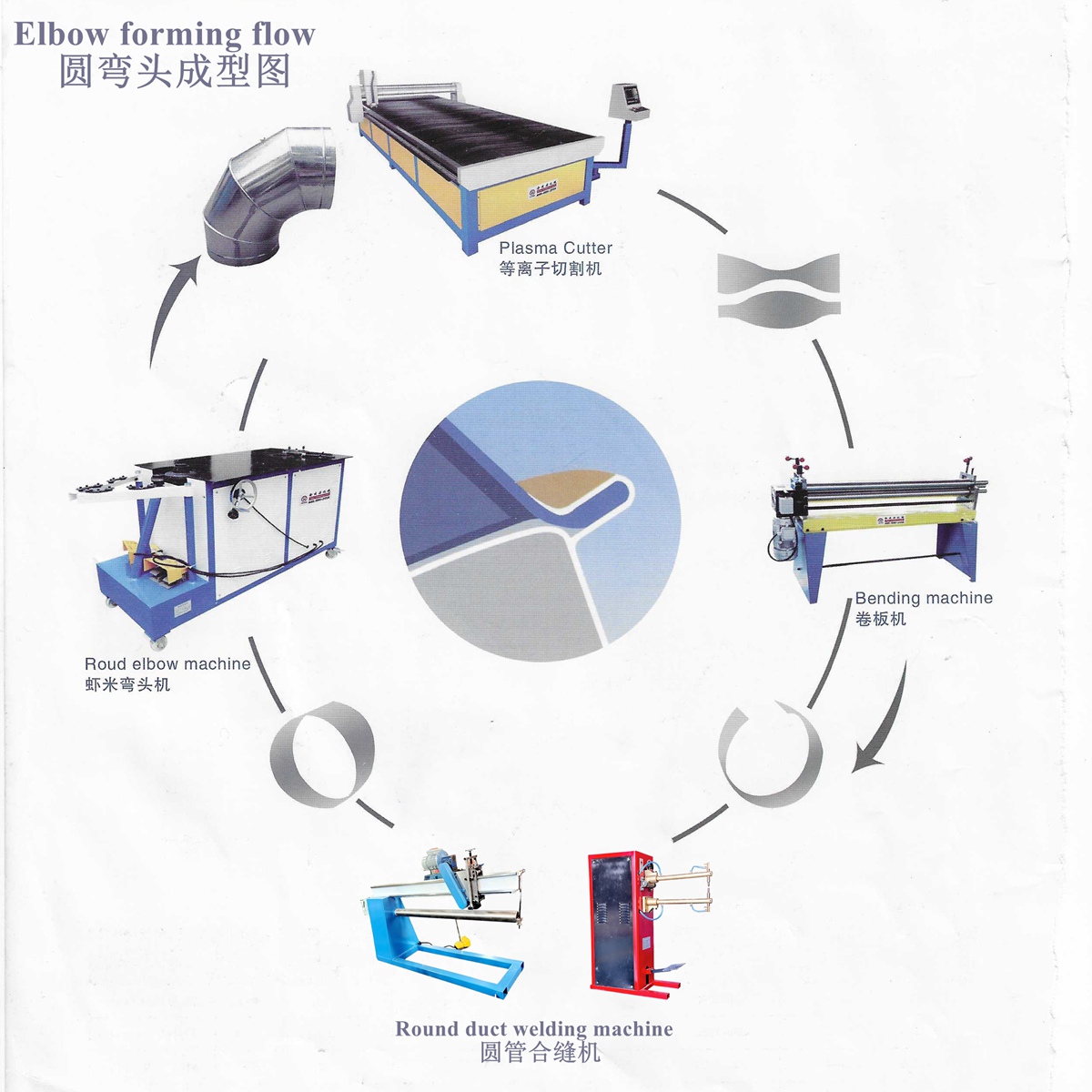

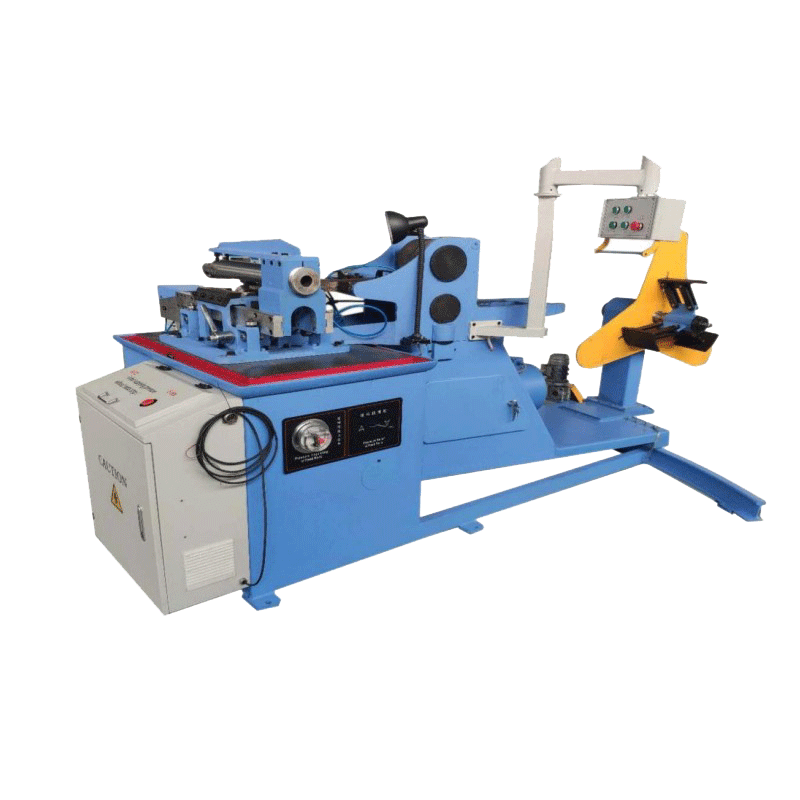

(1) Technological progress promotes industrial upgrading

With the continuous development of science and technology, air duct processing technology is also constantly improving. The application of advanced equipment such as CNC shearing machines, bending machines, and laser cutting machines has greatly improved processing accuracy and efficiency. At the same time, highly skilled welders use TIG or MIG welding technology to seamlessly connect various components to ensure the air tightness and durability of the air duct. In the future, the air duct processing industry will pay more attention to technological innovation and application, and promote industrial upgrading and high-quality development.

(2)Market demand continues to grow

With the acceleration of urbanization and people's higher requirements for quality of life, the market demand for building ventilation and air conditioning systems continues to grow. At the same time, the rapid development of industrial production has also led to an increase in the demand for exhaust systems. In addition, as the concept of green building becomes more and more popular, the application prospects of air duct processing products in the field of energy conservation and environmental protection are also very broad.

(3)Customized services have become a trend

With the intensification of market competition and the diversification of customer needs, customized services have become an important trend in the air duct processing industry. Air duct processing factories need to provide customized ventilation management solutions based on customers' specific needs and process requirements. This includes selecting appropriate air duct materials, designing a reasonable duct layout, formulating installation and commissioning plans, etc. By providing customized services, air duct processing factories can better meet customer needs and enhance market competitiveness.

(4)Intelligent development leads the future

In the future, the air duct processing industry will pay more attention to intelligent development. By introducing advanced technologies such as intelligent processing equipment and intelligent control systems, we can realize the automation, intelligence and refinement of air duct processing. This can not only improve production efficiency and product quality, but also reduce labor costs and energy consumption, pushing the industry to develop to a higher level.

To sum up, air duct processing products are an indispensable and important component of building ventilation systems, air conditioning systems and industrial exhaust systems. They are widely used and have broad prospects. With the continuous advancement of technology and the continued growth of the market, the air duct processing industry will usher in better development prospects.