Why Spiral Duct Machines Are Essential for Energy-Efficient Building Projects

Aug 07, 2025

In the era of green buildings and energy-efficient HVAC systems, Spiral Duct Machines have become a hot topic across the global construction and ventilation industry. With stricter energy codes and higher standards for indoor air quality, contractors are shifting towards spiral ductwork for its superior performance and long-term value.

Compared to rectangular ducts, spiral ducts offer less air leakage, lower pressure loss, and easier installation—making them the preferred choice in commercial, industrial, and cleanroom projects. As demand rises, manufacturers are seeking reliable and automated solutions to produce high-quality spiral ducts quickly and efficiently.

At Hecheng Source Machinery, our Spiral Duct Machines are designed to meet these evolving needs. Our machines can process galvanized steel, stainless steel, and aluminum, supporting multiple diameters and thicknesses. With PLC control, fast forming speed, and durable structure, our equipment is ideal for high-volume production.

Backed by nearly 10 years of experience and over 3,000 units sold globally, we provide not only machinery but also complete duct forming solutions—including customization, on-site training, and lifelong technical support. Whether you’re a local workshop or a global HVAC supplier, our spiral duct machines will help you enhance your output and product quality.

Now is the time to upgrade your production with smart, reliable, and efficient equipment.

I. Spiral ducting Machine's Features:

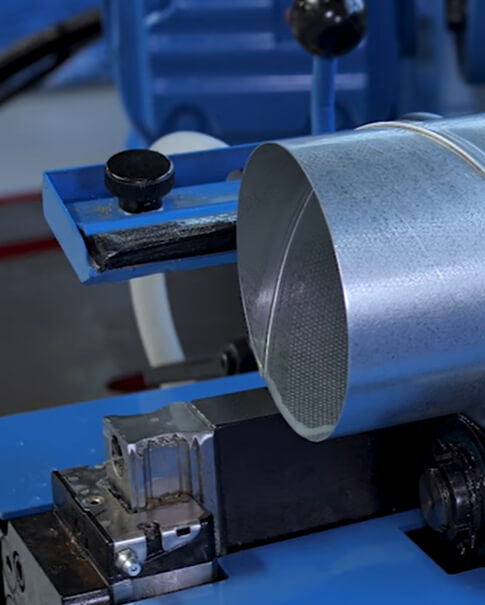

Spiral ducting machine is used for producing HVAC round duct. Spiral duct is made of metal strip rolled into a spiral bite wall of the thin tube, round, no welding, no leakage. The spiral ducting machines produced by HCY company have high yield and stable pipe diameter, and good bite, good sealing, long-term innovation.

1.Spiral ducting machine with patented mold which has its own patent and easy to adjust, save the metal strip.

2.High-speed synchronous cutting system

3.PLC control

4.Can be on-site construction

5.Can be adjusted

6.High-quality products, high-quality services

7.The system can handle galvanized sheet, aluminum

8.automatic roll out of equipment

9.Can produce a variety of different diameter spiral tube

II. Technical Parameters

1. Name: Spiral ducting machine HCY-2.0-2000

2. Diameter range: Φ100-Φ2000mm

3. Tube length: 100-12000mm

4. Strip width: 137mm

5. Lock seam: Outside tube,on the inside on request

6. Material Galvanized sheet: 0.4-2.0mm

7. Strip speed: 38m/min

8. Dimension: 3400x2070x2720mm

9. Weight: 2300kg

10. Control system: PLC automatic control

11. Main motor power: 16.5KW

12. The power of cutting motor: 4KW

13. Electrical: 380V/50HZ/3PH Voltage customized

14. Welding machine: Huanyuan 100A